Why Maxwatt !

Products & Services

Brochure

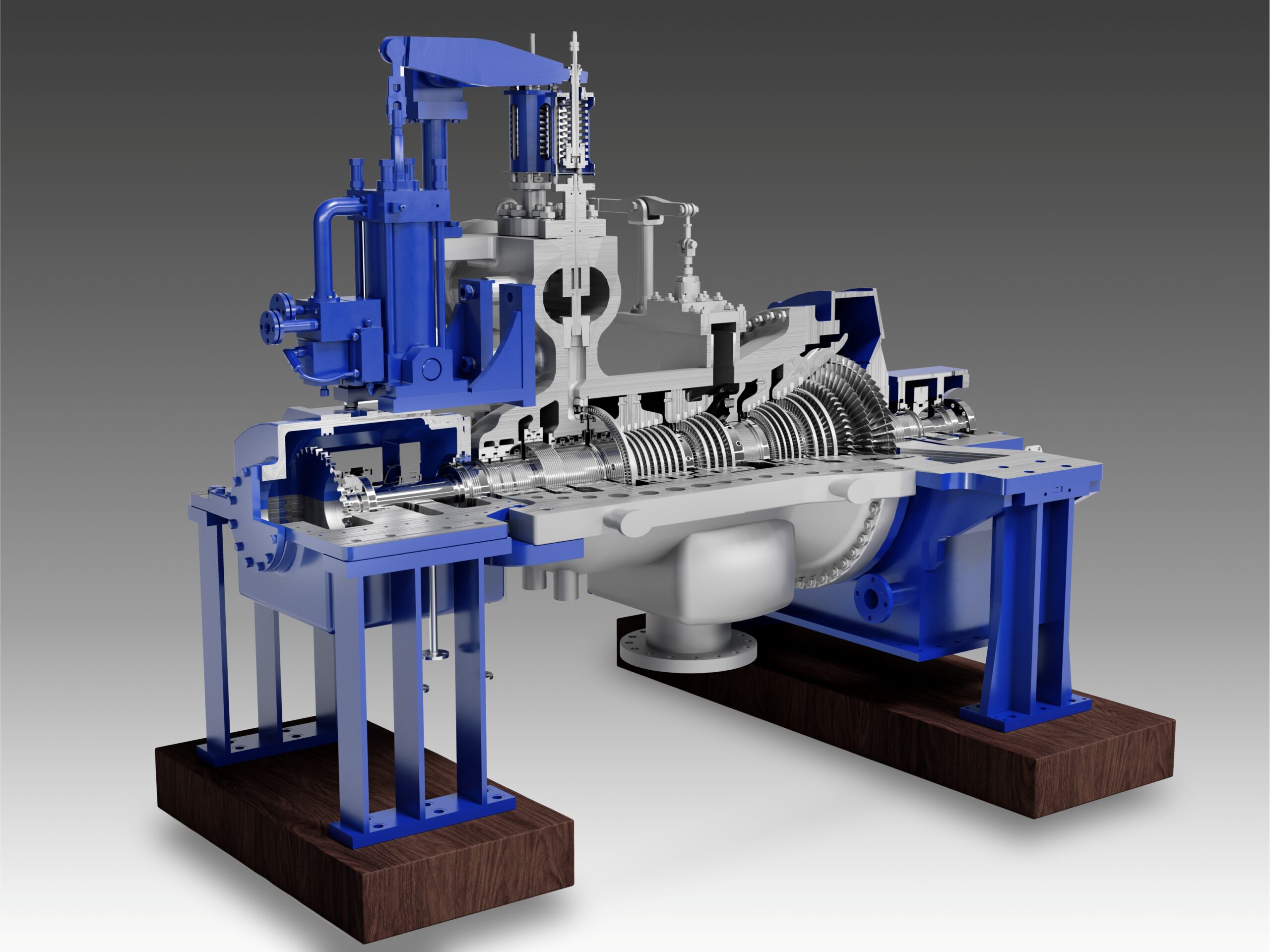

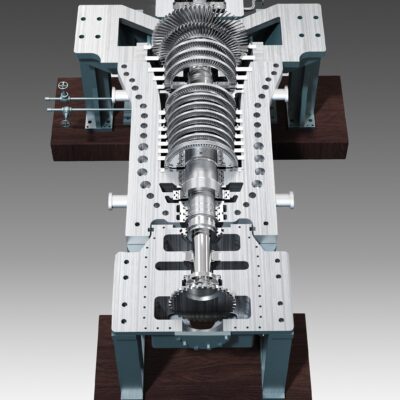

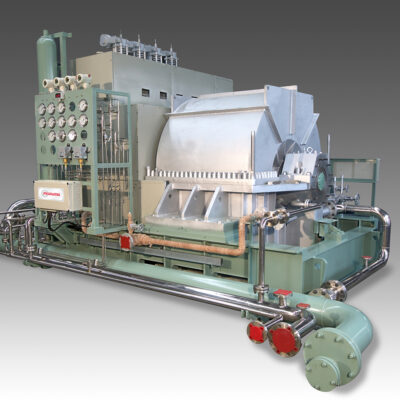

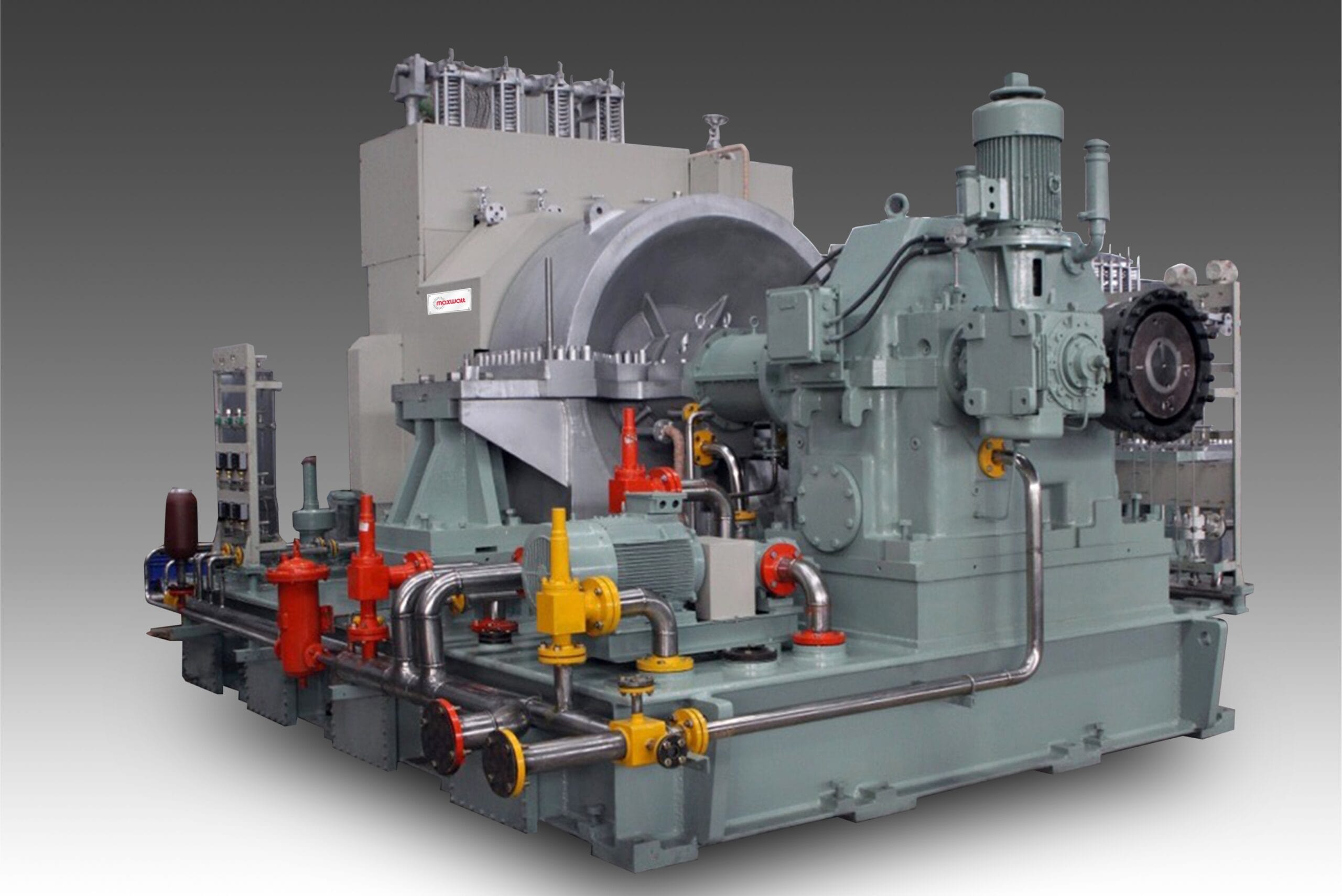

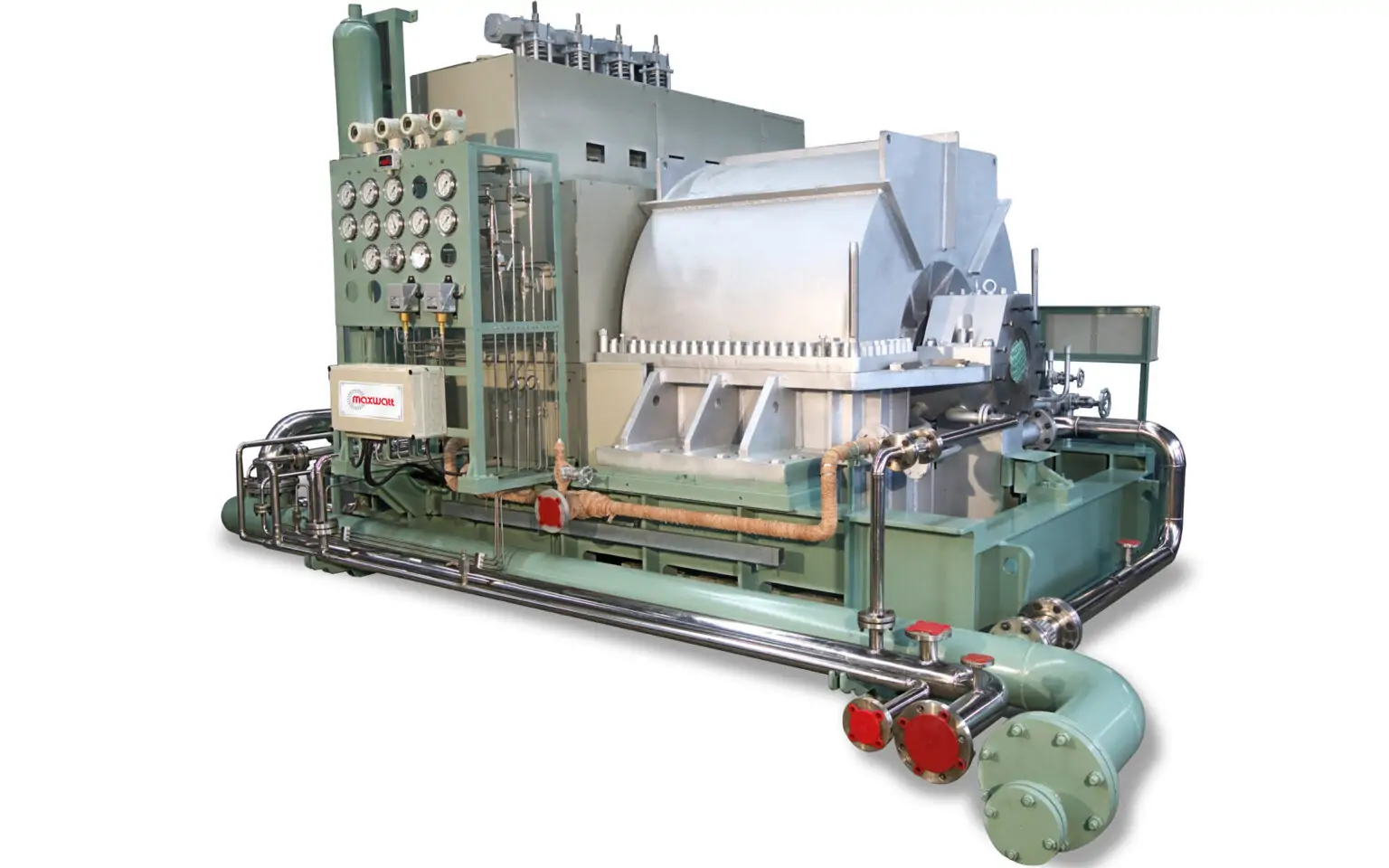

Maxwatt manufactures a comprehensive range of impulse and reaction design, steam turbines

in 50 kW – 20,000 kW range. We can offer a fully integrated mechanical or Cogeneration or Power Generation package using any of the following turbine type ;

- Back-pressure

- Extraction (Injection) cum back pressure

- Condensing

- Extraction (Injection) cum condensing

Our turbines have a reputation for delivering exceptional performance and reliability, and there are several key factors that contribute to this success. By prioritizing these critical aspects, we are able to consistently meet and exceed the expectations of our customers, ensuring that our turbines are trusted solutions for their critical operations.

Model and Rating

- Type - Reaction / Impulse

- Configuration - Back Pressure / Condensing

- Extraction - With / Without Extraction

- Nominal Rating - Up to 20,000 KW

- Inlet Steam Pressure - Up to 120 Ata

- Inlet Steam Temperature - Up to 525°C

- Maximum Exhaust Pressure - Up to 15 Ata

- RPM - Up to 12,000

- Design & Development

- Manufacturing

- Quality Assurance

- After - sales care

Our designs undergo continuous monitoring and optimization, leading to enhanced product reliability and performance. This approach significantly reduces the time required to implement new development programs.

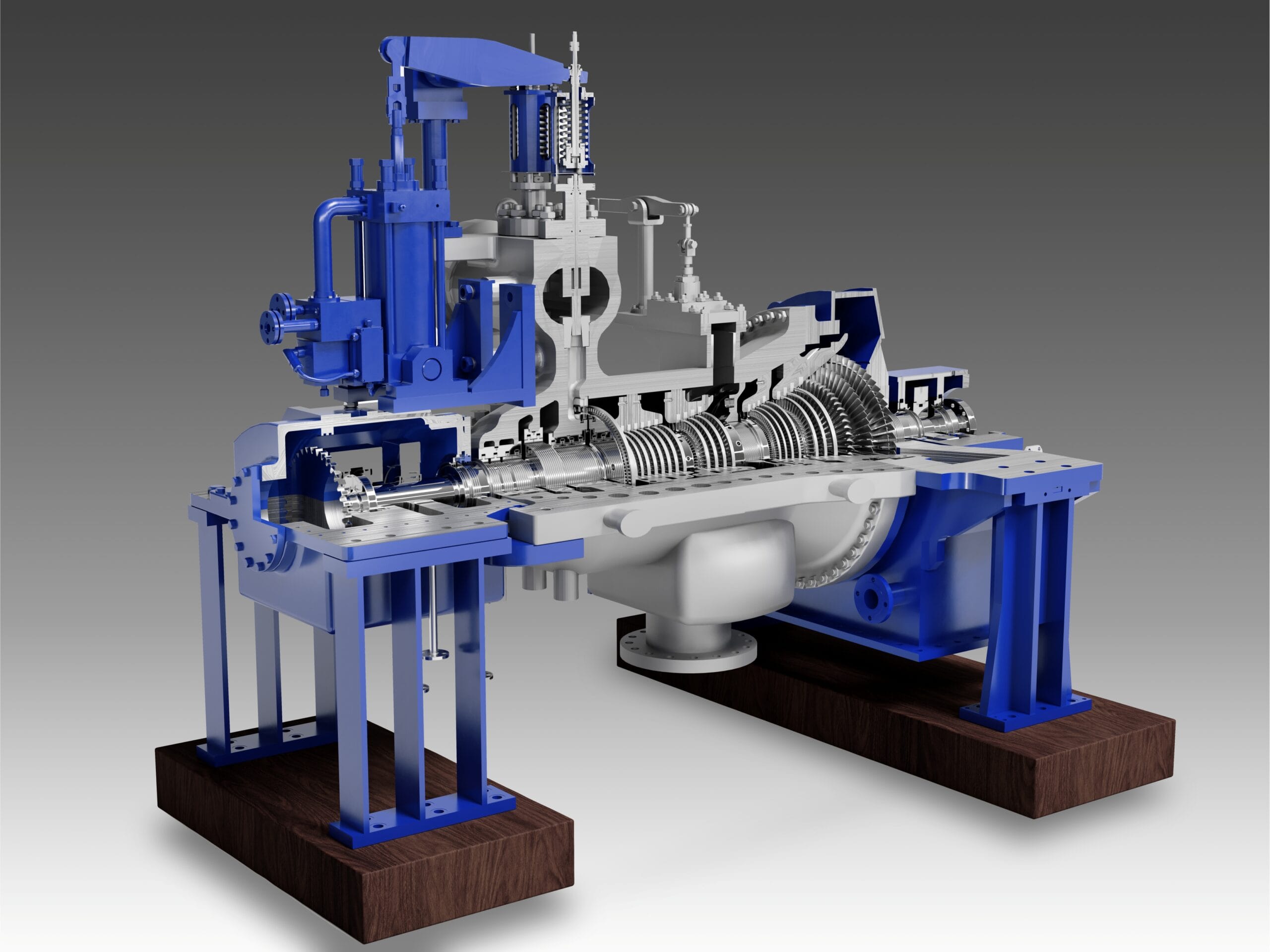

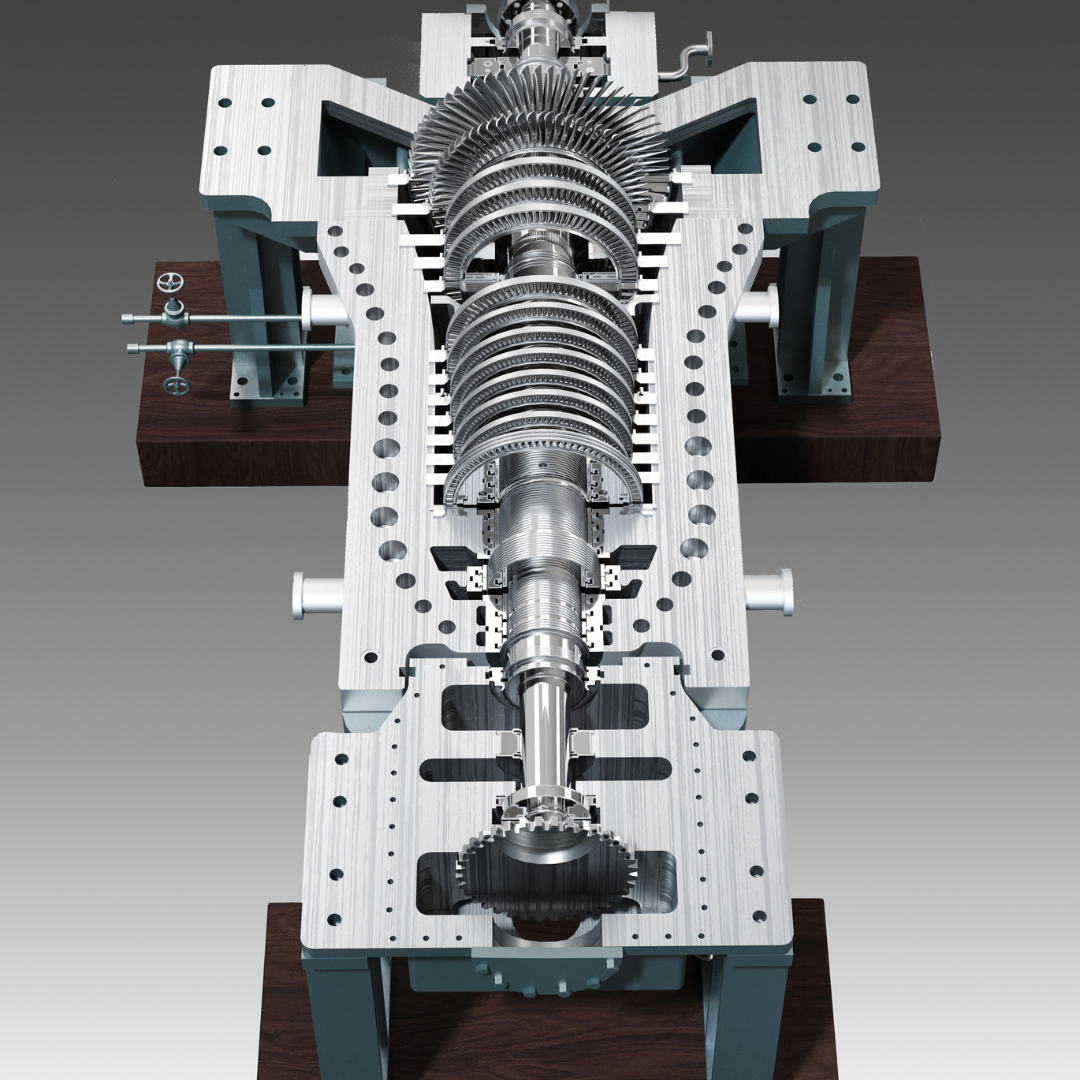

The design and development facilities feature tailored and specialized software tools for fluid flow path analysis, thermodynamic design, critical speed and torsion analysis, blade vibration assessment, stability analysis, heat transfer analysis, as well as tools for 3D modelling and 2D designs.

The design approach is based on using standardized modules to offer custom-built machines which are compact and rugged, yet simple in design. The expertise, combined with incorporation of many time tested features and use of sophisticated development and engineering tools, contributed to development of an outstanding range of steam turbines.

We take pride in our skilled and multi-disciplinary team of engineers, all dedicated to fulfilling our customers’ needs. Our turbine development team boasts a collective experience spanning hundreds of years across various facets of steam turbine technology, including:

Thermodynamic Design

Mechanical Design

The design approach is based on using standardized modules to offer custom-built machines which are compact and rugged, yet simple in design. The expertise, combined with incorporation of many time tested features and use of sophisticated development and engineering tools, contributed to development of an outstanding range of steam turbines.

We take pride in our skilled and multi-disciplinary team of engineers, all dedicated to fulfilling our customers’ needs. Our turbine development team boasts a collective experience spanning hundreds of years across various facets of steam turbine technology, including:

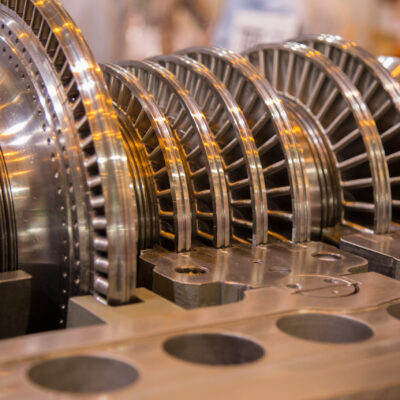

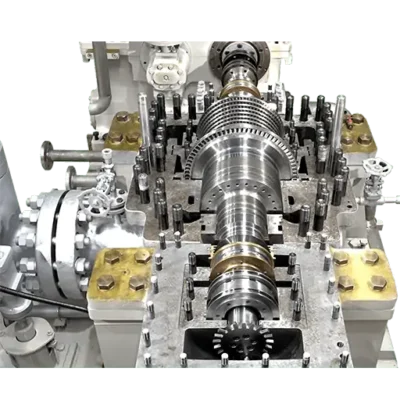

Manufacturing process embodies a fusion of in-house resources and the strategic outsourcing of machining operations to meticulously vetted machining facilities. Our commitment to quality outsourcing is not only assured but fortified by rigorous controls and vigilant supervision at every stage. The objective in every facet of the manufacturing process is to consistently enhance the value of our customized products.

From raw material procurement to component production, product assembly, and comprehensive testing, each step adheres to a well-established in-house process, ensuring the utmost precision and reliability.

A predetermined process is followed to record every activity / manufacturing results.

We regard quality as a continuous journey, one that enhances the value we provide, leading to customer preference for our products, and thereby contributes to the growth of our organization and its dedicated teams.

Our commitment to ensuring quality is defined by four key pillars:

Comprehensive Quality Assurence Plan

Stringent Production Control

Collaborative Vendor Engagement

Continuous Learning and Enhancement

At Maxwatt, we consider after-sales care an integral part of our operational philosophy, prioritizing optimal equipment performance while minimizing downtime. We stand ready to assist our customers 24/7, offering rapid response and support in case of equipment-related outages. Furthermore, we maintain a comprehensive inventory of spare parts to promptly address any unforeseen equipment disruptions.

Our adept team of field technicians and engineers is well-prepared to manage a full spectrum of services, including package installation, commissioning, performance monitoring, maintenance, and repair. This proficiency extends not only to our own turbines but also to those from other manufacturers, ensuring that your equipment receives top-tier attention.

Our customer care team goes the extra mile by conducting tailored training programs, both on-site and at our facility, designed to meet the unique needs of each customer. This comprehensive approach underscores our unwavering commitment to your success and satisfaction.

| Attribute | Details |

|---|---|

| Type | Reaction / Impulse |

| Configuration | Back Pressure / Condensing |

| Extraction | With / Without Extraction |

| Nominal Rating | Up to 20,000 KW |

| Inlet Steam Pressure | Up to 120 Ata |

| Inlet Steam Temperature | Up to 525°C |

| Maximum Exhaust Pressure | Up to 15 Ata |

| RPM | Up to 12,000 |

Our designs undergo continuous monitoring and optimization, leading to enhanced product reliability and performance. This approach significantly reduces the time required to implement new development programs.

The design and development facilities feature tailored and specialized software tools for fluid flow path analysis, thermodynamic design, critical speed and torsion analysis, blade vibration assessment, stability analysis, heat transfer analysis, as well as tools for 3D modelling and 2D designs.

Manufacturing

Manufacturing process embodies a fusion of in-house resources and the strategic outsourcing of machining operations to meticulously vetted machining facilities. Our commitment to quality outsourcing is not only assured but fortified by rigorous controls and vigilant supervision at every stage. The objective in every facet of the manufacturing process is to consistently enhance the value of our customized products.

From raw material procurement to component production, product assembly, and comprehensive testing, each step adheres to a well-established in-house process, ensuring the utmost precision and reliability.

- Vestibulum consectetur lorem interdum, sollicitudin sapien ac, laoreet magna.

- Proin vel arcu pulvinar, feugiat urna in, laoreet tortor.

- Curabitur pulvinar nulla eget libero facilisis fringilla.

Industriel is a pioneer in design-build specializing in architecture and construction services. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

Industriel has a brilliant record in responding to complex customer requirements. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

We work to reduce air emissions associated with our operations and the products we deliver. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

Quality Assurance

At Maxwatt, we regard quality as a continuous journey, one that continually enrhances the value we provide, leading to customer preference for our products, and thereby contributes to the growth of our organization and its dedicated team.

Our commitment to ensuring top-notch quality is defined by three key pillars:

Sales Care

At Maxwatt, we consider after-sales care an integral part of our operational philosophy, prioritizing optimal equipment performance while minimizing downtime. We stand ready to assist our customers 24/7, offering rapid response and support in case of equipment-related outages. Furthermore, we maintain a comprehensive inventory of spare parts to promptly address any unforeseen equipment disruptions.

Our adept team of field technicians and engineers is well-prepared to manage a full spectrum of services, including package installation, commissioning, performance monitoring, maintenance, and repair. This proficiency extends not only to our own turbines but also to those from other manufacturers, ensuring that your equipment receives top-tier attention.

Our customer care team goes the extra mile by conducting tailored training programs, both on-site and at our facility, designed to meet the unique needs of each customer. This comprehensive approach underscores our unwavering commitment to your success and satisfaction.