Mechanical Vapour Compression (MVR) technologies, a longstanding presence in industry,

have gained increased attention, especially with the growing emphasis on Environmental,

Social & Governance (ESG) factors in corporate settings. As the importance of energy

efficiency takes centre stage among various technologies, steam remains a prevalent

medium for heat transfer in numerous industries. However, many heat transfer applications

result in the release of steam vapours, dissipating energy into the environment through

cooling towers.

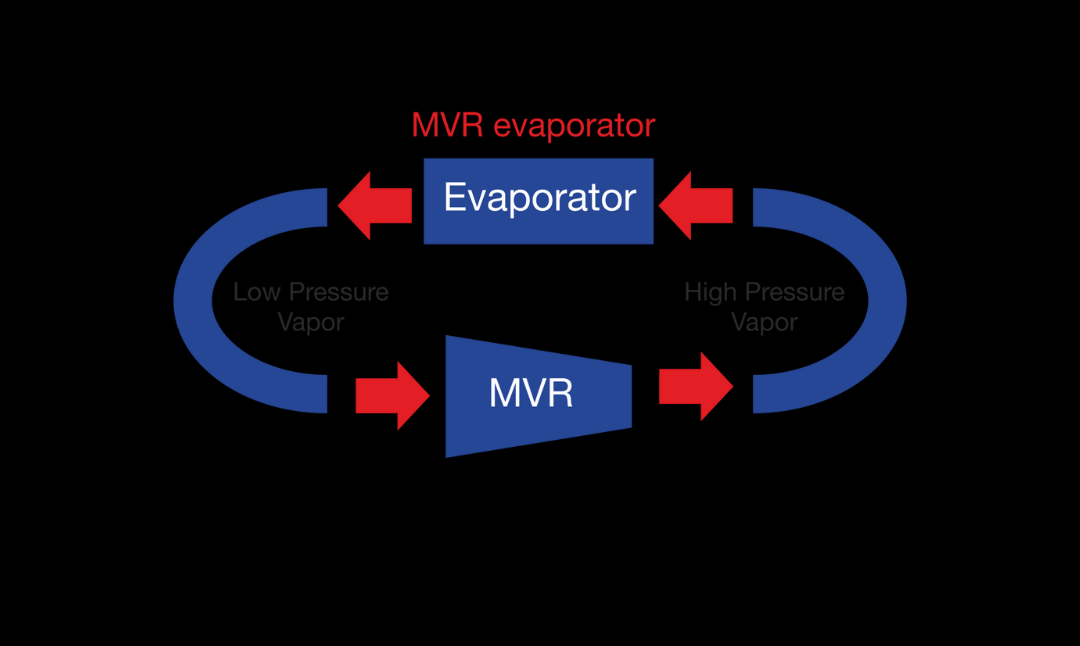

The Mechanical Vapour Recompression Process addresses this challenge by re-compressing

the vapours produced during evaporation back to their original state, effectively recycling

latent heat. These re-compressed vapours are then reintroduced into the evaporation cycle

as the motive heat source. In traditional steam generation processes, a substantial amount

of energy is consumed during the phase change of water to steam (Latent Heat – 540

Kcals/Kg). The MVR process optimizes this by recycling the latent heat of steam, offering a

two-fold advantage:

1. Elimination of fossil fuel consumption for steam generation in evaporation.

2. Significant reduction in total energy costs, resulting in a rapid payback period and a

compelling return on investment when integrated with a heat transfer process.

Maxwatt offers a comprehensive range of Vapour Fans & compressors for MVR application.

All these Fans and compressors are designed based on Centrifugal and Axial compression

technologies