Products & Services

Our range of services include:

- Critical spare parts support

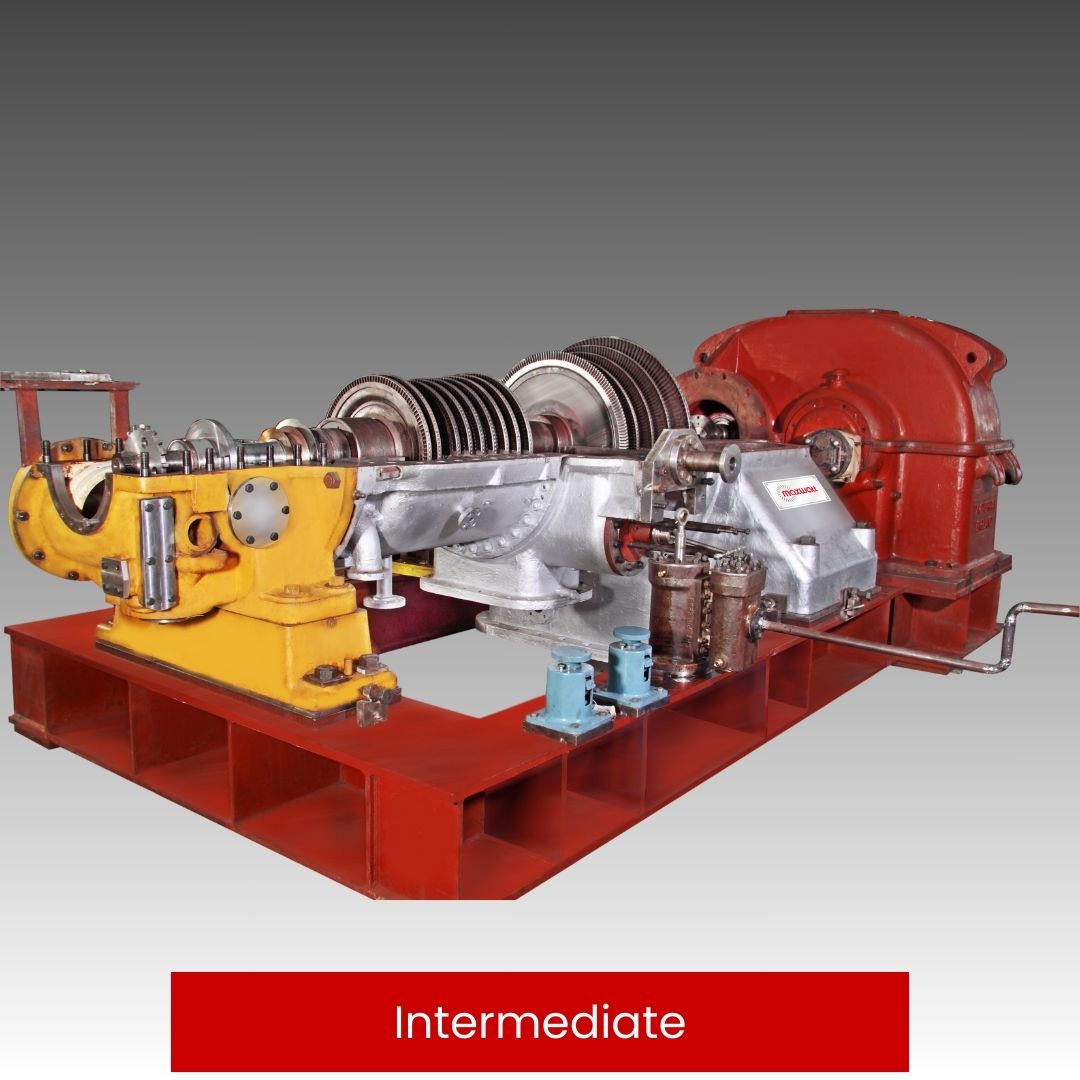

- Component repair & remanufacturing solutions.

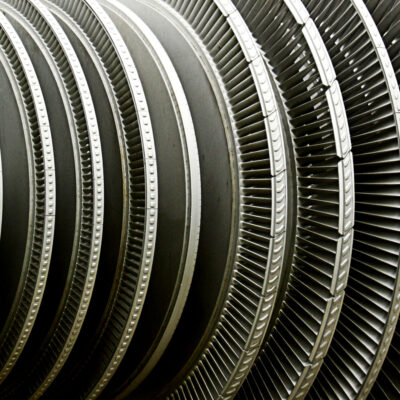

- Re-engineering for efficiency enhancement & Upgrade solutions

- Refurbishing and modification of steam path.

- Governor-retrofitting solutions (Hydro-mechanical to electronic).

- Steam path inspection assistance and overall health analysis for old turbines.

- Reverse Engineering

- Flow path modification

Some Of The Makes Handled

- ABB

- Alstom

- Coppus Murray

- Dresser Rand

- Elliott

- Escher Wyss

- GEC

- Kawasaki

- MAN ES

- Metropolitan Vickers

- Mitsubishi

- Peter Brotherhood

- Terry Corporation

- Shin Nippon

- Siemens

- SKODA

- Terry

- Triveni

- Westing House

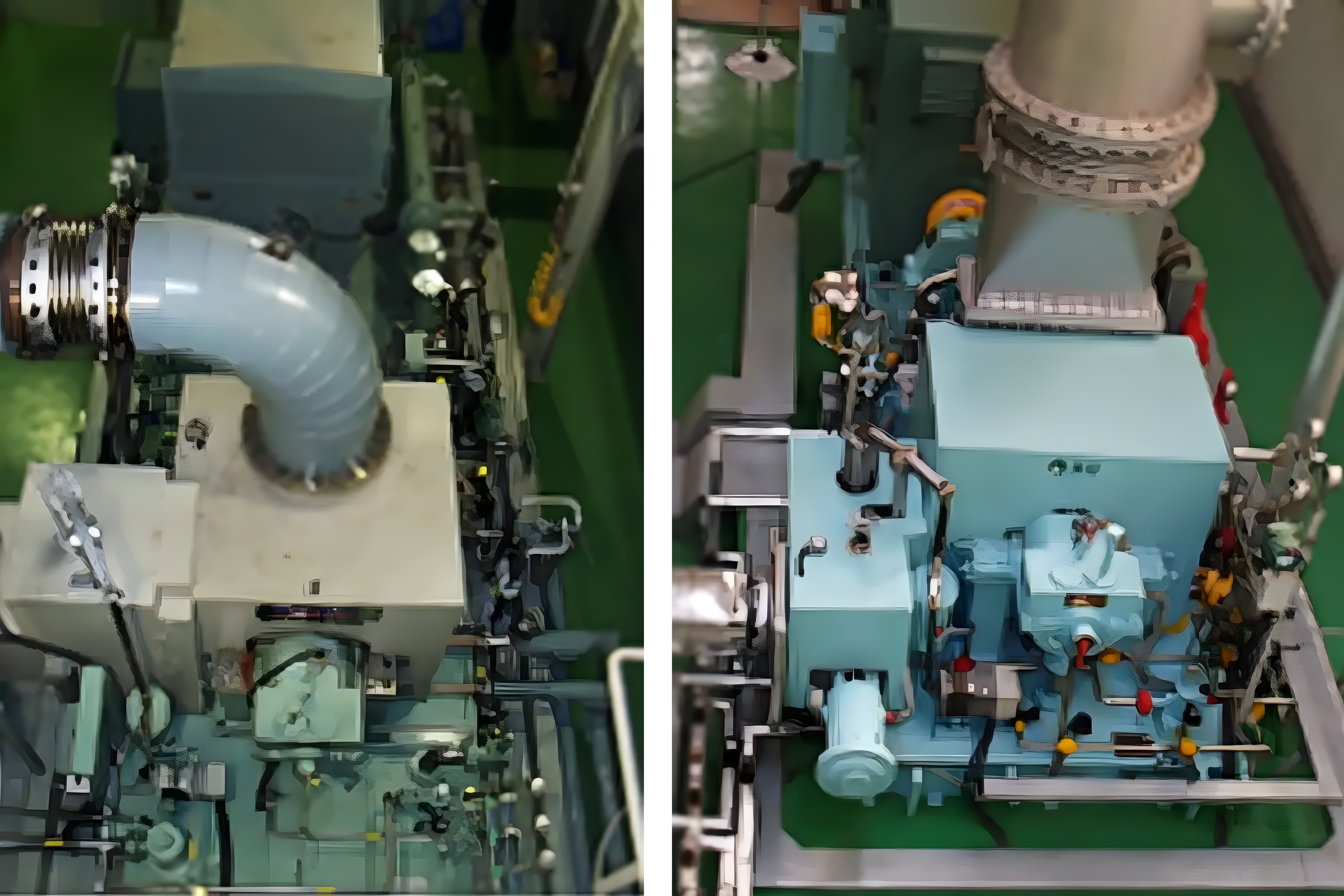

At Maxwatt, we take immense pride in our team’s extensive expertise in the refurbishment and enhancement of steam turbines. Our company’s roots trace back to the establishment of Pentagon Turbo Engineers Pvt. Ltd. in 1992, founded by a group of seasoned turbomachinery specialists. With a remarkable track record that spans the successful handling of over 1000 steam turbines from 25 different manufacturers, in ratings from 50 KW – 30 MW, our team of turbine technologists possesses profound knowledge and proficiency in the realm of steam turbines.

Our team’s robust background in the After Sales business, combined with the experience of being a full-fledged steam turbine manufacturer, places us in a formidable position to offer a comprehensive suite of services tailored to your After Sales needs.

Our unwavering commitment to delivering customer-centric solutions is the bedrock of our business, and we take great pride in our ability to provide our customers with the highest caliber of service.

Our range of services include:

Modern industrial engineers typically use predetermined motion time system, computer simulation, along with extensive mathematical tools for modeling, such as mathematical optimization and queueing theory, and computational methods for system analysis, evaluation, and optimization.

- Critical spare parts support

- Component repair & remanufacturing solutions.

- Re-engineering for efficiency enhancement & Upgrade solutions

- Refurbishing and modification of steam path.

- Governor-retrofitting solutions (Hydro-mechanical to electronic).

- Steam path inspection assistance and overall health analysis for old turbines.

- Reverse Engineering

- Flow path modification

Some Of The Makes Handled

- ABB

- Alstom

- Coppus Murray

- Dresser Rand

- Elliott

- Escher Wyss

- GEC

- Kawasaki

- MAN ES

- Metropolitan Vickers

- Mitsubishi

- Peter Brotherhood

- Terry Corporation

- Shin Nippon

- Siemens

- SKODA

- Terry

- Triveni

- Westing House

Our Solutions & Benefits

Electronic materials are the type of materials which are typically used as core elements in a variety of device applications. These elements can be, for example, memories, displays, LEDs and could be easily seen in daily electronic gadgets such as mobile phones, computers, laptops, tablets, GPS devices, LED bulbs, TVs and monitors.

Industriel is a pioneer in design-build specializing in architecture and construction services. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

Industriel has a brilliant record in responding to complex customer requirements. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

We work to reduce air emissions associated with our operations and the products we deliver. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the simila.

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.